ALLDROP® nanoDispenser

In-line control of nanoliter dispensing processes implements highest reproducibility and full traceability.

100% IN-PROCESS CONTROL

Autonomous volume adjustment

Track, verify and guarantee droplet volumes.

Each droplet is imaged by the integrated camera system during dispensing. The image is processed immediately, calculating the droplet volume and verifying the droplet quality. Our intelligent software algorithm notices a volume drift and automatically regulates the droplet volume for the most reliable and reproducible results.

OUTSTANDING BENEFIT IN

Personalized medicine

Pharma production

Diagnostic manufacturing

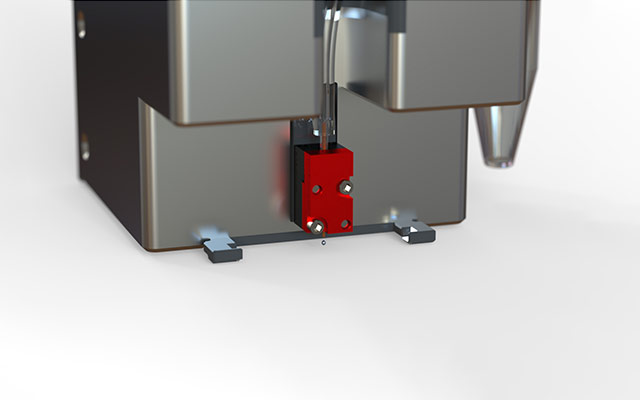

Printhead for highest requirements

A printhead designed for OEM integration into production lines or existing automation platforms.

- Drop-on-demand, non-contact dispensing technology

- Nanoliter single droplet volume

- Integrated imaging calibration and regulation tool

- Low cost consumable 'dispensing pipe'

Fully documented process

100% traceable

Integration-ready

Wide range of different liquids

Highest reproducibility

Non-contact nanoliter dispensing

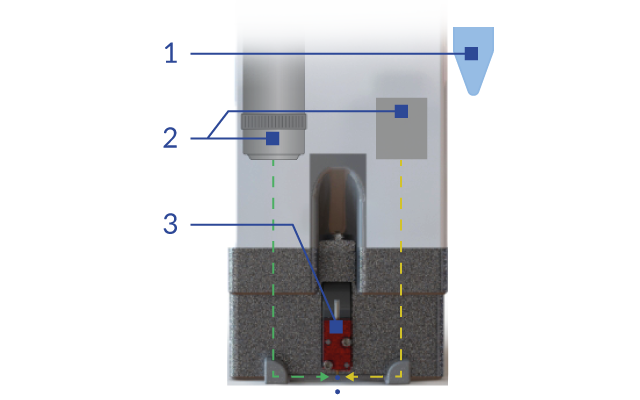

ALLDROP® technology

Smartly combined

SMARTRESERVOIR, SMARTDROP® and PIPEJET® nanoDispenser combined to create the smartest printhead.

1. SMARTRESERVOIR - Enables the precise control of pressure conditions ensuring stable dispensing results with different liquids at high frequency

2. SMARTDROP - Volume calibration and verification by droplet imaging for an automated in-line control of droplet size and quality.

3. PIPEJET® - Non-contact dispense unit for generating single droplets in the nanoliter range. The fluid capillary 'dispensing pipe' is separated from the actuator avoiding time consuming cleaning or maintenance.